Qianhai Shimao Building

Shenzhen, Guangdong

Qianhai Shimao Building is located at Block 03, Unit 19, Shenzhen-Hong Kong Cooperation Zone, Qianhai, Shenzhen. "Business" is integrated, integrating various personalized design requirements, and is committed to building a corporate business card with an international benchmark in the Bay Area.

The tower form of Qianhai Shimao Tower is derived from nature. Two volumes rise from the ground, towering into the clouds, forming a perfectly unified, independent and closely intertwined relationship. With the world's first 45° double-rotating art building, it perfectly presents the fusion of the architectural aesthetics and visual effects of the "God Curve" to achieve the ultimate beauty and artistry. A new landmark symbolizing the eternal connection and harmonious unity of the two sides of the strait was born.

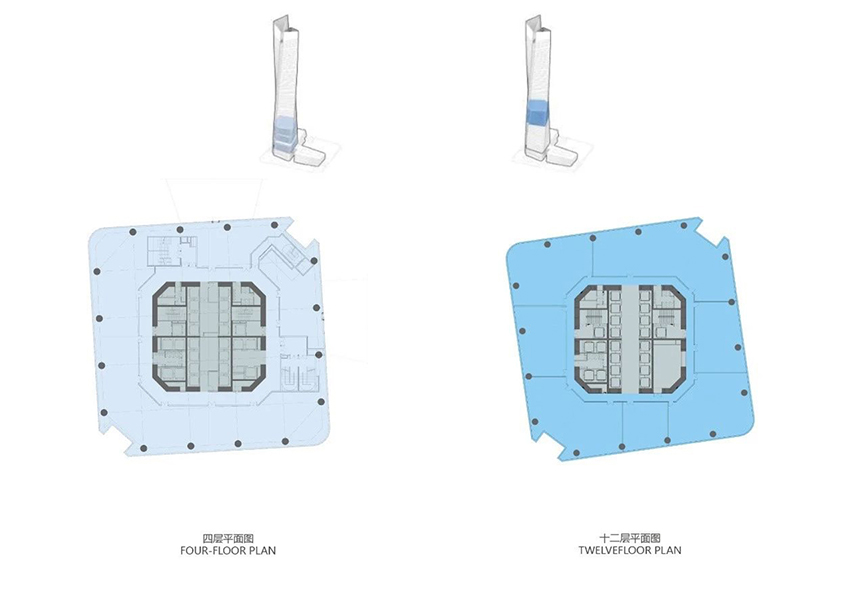

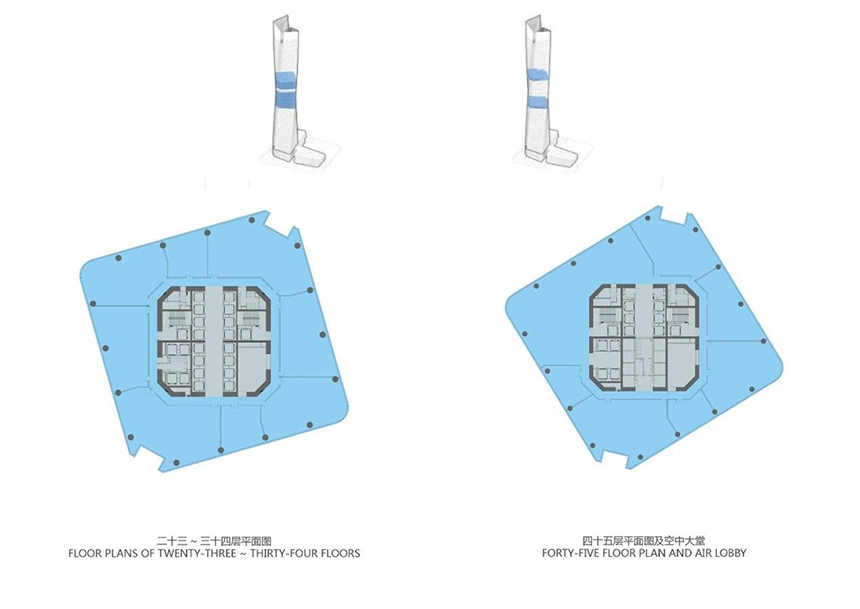

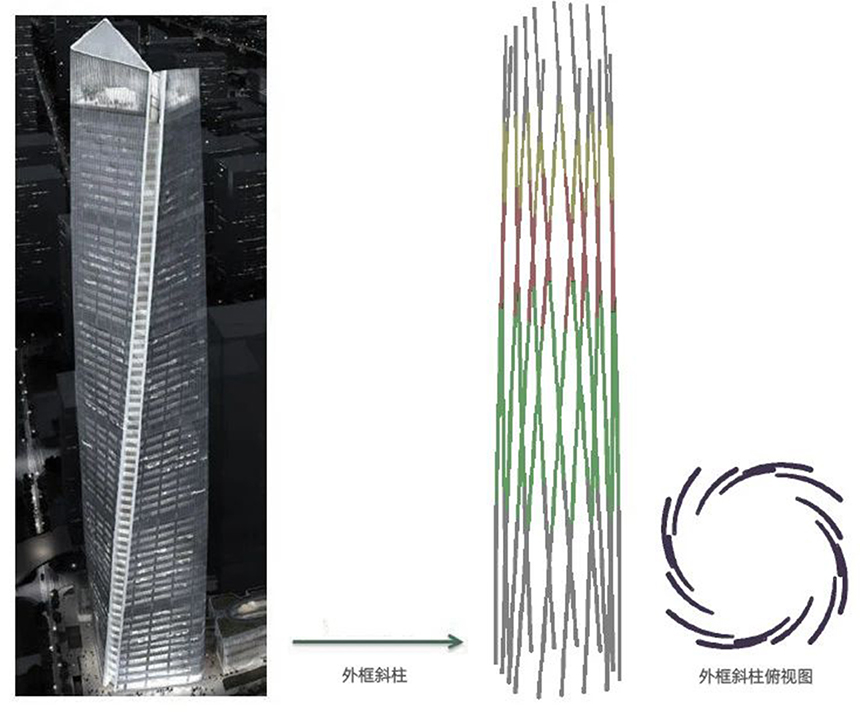

The tower adopts an unconventional inclined column frame-core tube structure system. The outer frame is a steel tube concrete inclined column and steel beam structure, and the core tube is a reinforced concrete structure. The plan of the tower building plan is approximately square, and the bottom floor area is large, and gradually shrinks as the height increases, creating a stable structural feeling in a retracted manner.

The wind tunnel test study shows that when the tower rotates to 45°, the wind-induced load is reduced by about 10%. At the same time, the preliminary analysis results of the structure show that when the floor shear distribution is close, the tower will not rotate, rotate 30°, rotate 45°, and rotate 60°, and produce the outer frame corners except the vertical load. It will be different except that the difference in the distribution ratio of structural period, displacement angle, inner and outer cylinder shear force, and bending moment is small. Comprehensive building shape and structural load and force characteristics, the implementation plan finally adopts the plan of building rotation 45°.

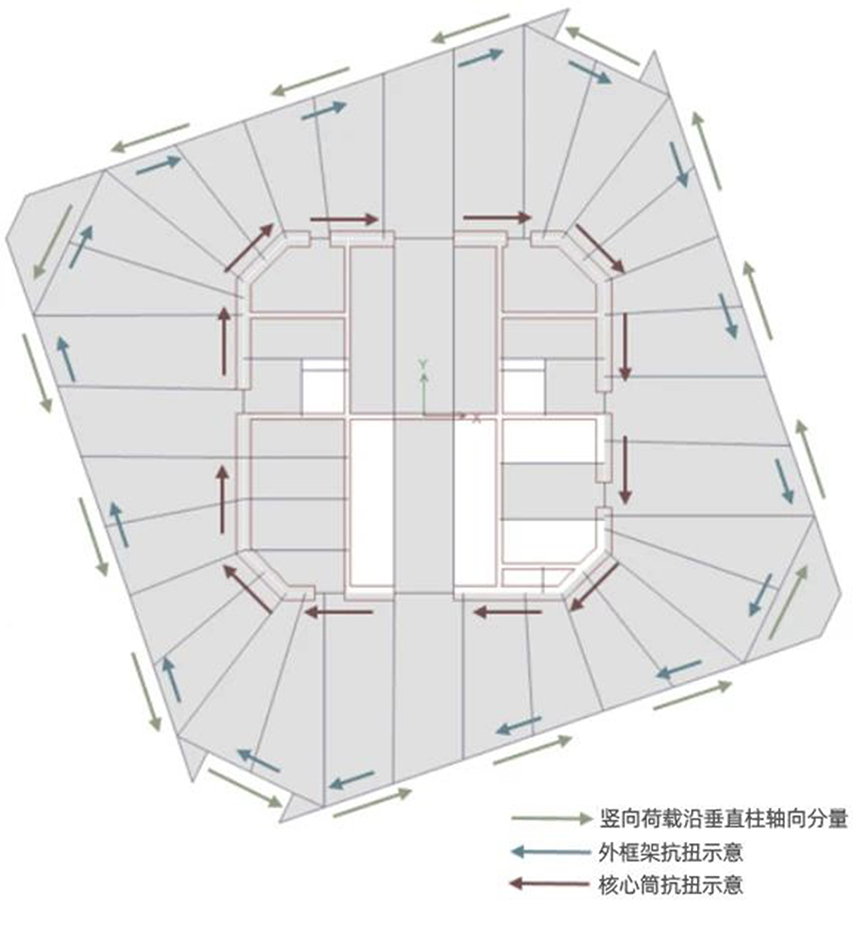

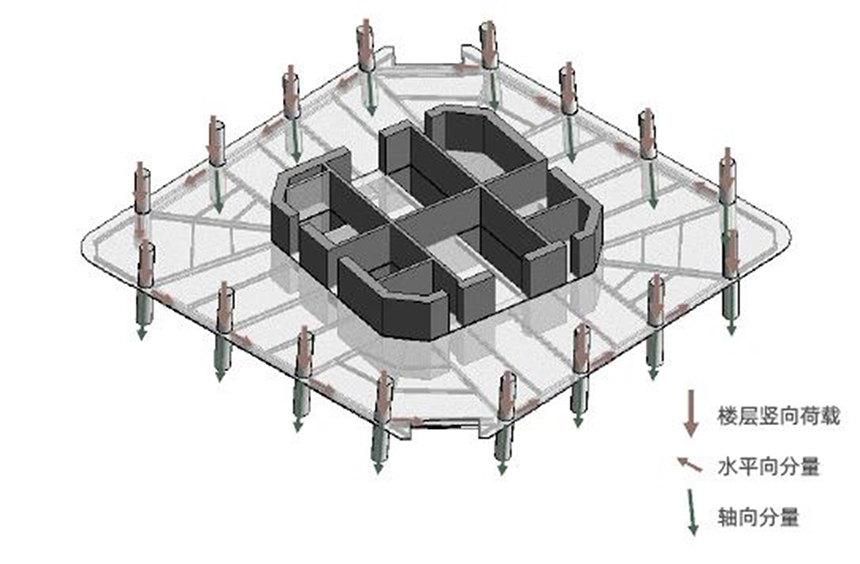

Under the action of horizontal load, the force and deformation characteristics of the conventional frame-core tube are similar, but under the action of vertical load, there is a big difference. The study of the vertical load transfer path shows that: after the vertical load of each layer is transferred to the outer frame column and the core tube in a conventional manner, the core tube part of the load continues to be transferred downwards, and the inclined outer frame column converts part of the load into The other part of the oblique axial force along the axis of the column is transformed into a horizontal force, and a horizontal force circulation is formed at the outer frame to generate torque on the core tube.

The core tube torque exists in the form of shear circulation in the core tube shear wall. The horizontal force formed during the vertical load transfer process of the floor is characterized by the torque to the core tube at the outer frame of each layer is only related to the vertical load of the layer. But it does not accumulate layer by layer, and the torque of each layer of core tube is accumulated layer by layer.

Different from the conventional frame-core tube structure, under the action of gravity load, the torque transmitted from the floor slab to the core tube is transformed into the shear force of the core tube shear wall, which causes the main tension force in the oblique direction on the wall. The connection of the floor slab with the beams and columns and the core tube is very important, and its performance plays a decisive role in the safety of the structure.

In addition to connecting the outer frame with the core tube and transmitting the horizontal load, the floor slab also transmits the horizontal force generated by the vertical load. The connection structure of columns, beams and slabs is within the range of double the column diameter from the column side outwards, and circular steel bars are installed to strengthen the connection between the columns and the slab. At the same time, studs are set on the beam to increase the reinforcement ratio of the steel bar in the wide range of the outer frame beam. The connection between the slab and the core tube is that the shear force transmitted by the floor slab does not exceed the limit of the shear section, and the distributed steel bars between the floor slab and the core tube are checked against shear slippage.

The façade of the tower is based on the concept of "harmony"—the same volumes that are hinged to each other constitute a subtle visual balance. The arcs and 45° straight edges and chamfers rotate evenly with the overall volume, forming two beautiful three-dimensional control lines on the facade to strengthen the morphological characteristics of the project. In the design of the curtain wall, the "story" is used as the unit to follow the contraction of the tower plane, so that the curtain wall panel size of each floor is continuously reduced, from 1560mm at the bottom to 1250mm at the top; The rods effectively magnify the towering sensory effect from the perspective of people.

Project Name: Qianhai Shimao Building

Project location: Shenzhen City, Guangdong Province

Project function: office, commercial

Building area: 190,000 square meters

Building height: 294.3 meters (299.8 meters above sea level)

Project Director: Yang Weizhong

Project chief: Liu Xiaoying, Huai Yali

Architectural design: Xue Zhuoheng, Chen Xiaodong, Wang Longchuan

Structural design: Ma Zhenyan, Zhao Xuefeng, Wang Jinwen, Peng Hao, Li Qiang, Wang Ya

HVAC design: Ding Ruixing, Liu Hong, Hou Lianjian, Xie Zexin, Pan Xuhui

Electrical design: Wang Qing, Lu Shaofeng, Wan Chunni, Yao Zhi

Water supply and drainage design: Zhang Yongfeng, Zhu Xu, Jiang Xinglin

Intelligent design: Liu Yuhui, Yang Xiwei

BIM design: Zhao Baosen, Zhou Yunkai

Green Building Design: Lin Chaonan, Li Hongzhu

Cooperative units: Jinsi Architectural Design Office (Shanghai) Co., Ltd., Arup Engineering Consulting (Shanghai) Co., Ltd. Shenzhen Branch

Project owner: Qianhai Shimao Development (Shenzhen) Co.,